Home>Data Storage>14 Best Network Storage For 2024

Data Storage

14 Best Network Storage For 2024

Modified: January 6, 2024

Discover the top 14 network storage devices that offer secure and cost-effective data storage solutions for 2023. Find the perfect network storage for your business needs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

In the ever-changing world of technology, it's crucial to keep up-to-date on the latest gadgets and advancements. As we approach 2023, having reliable network storage will be essential for individuals and businesses alike. With so many options to choose from, it can be overwhelming to decide on the best fit for your needs. That's why we've compiled a list of the 14 Best Network Storage for 2023, so you can easily compare and choose the right one for you.

Overall Score: 9/10

The Synology 2 bay NAS DiskStation DS220+ is a great device for private cloud support with excellent performance and RAID 1 disk mirroring. Its Intel dual-core processor with AES-NI hardware encryption engine and 2 GB DDR4 memory make it great for photo indexing and database response time. The device features dual 1GbE LAN ports to support network failover and provide large sequential read and write throughput. The graphic user interface makes it easy to access, share, and sync data across different operating systems and devices. The device is optimized for SATA devices only. Although the device has some issues, it is an excellent choice for anyone looking to upgrade their home network storage capabilities.

Key Features

- Dual 1Gb E LAN ports for network failover

- Intel dual-core processor with AES-NI hardware encryption engine

- Access and sync data across different operating systems and devices

- 15% performance boost for photo indexing and other computing-intensive operations

- Graphic user interface

- RAID 1 disk mirroring

Specifications

- Color: Black

- Dimension: 6.50Lx4.25Wx9.14H

- Size: 2-bay; 2GB DDR4

- Unit count: 1

Pros

- Excellent performance

- Large app library

- Great private cloud support

- Easy to set up

- Robust safety features

Cons

- Plastic drive trays

- Certification issues with drives

- 1Gb Ethernet connection

- No integrated graphics for Plex server

The Synology 2 bay NAS DiskStation DS220+ is an excellent device for anyone looking to improve their home network storage capabilities. It is easy to set up, has robust safety features, and great private cloud support. Although it has some issues such as plastic drive trays and certification problems with drives, it is a great choice for anyone looking for reliable and efficient network storage.

Overall Score: 8/10

The BUFFALO LinkStation SoHo 220 is a robust network-attached storage system built for small offices and home use. The product offers up to 4 TB of disk space and is optimized to store, organize, share, and back up your important files. It comes with all the necessary hard drives installed, so no computer-based installation is required. The product supports subscriptions-free personal cloud storage, multiple PC backups, secure sharing with family and friends, and an SSL-encrypted file transfer system that keeps your data safe. It also offers a Direct Copy function to back up your devices via USB. Its interface is a bit underdeveloped but reasonably functional for most home users. The product has a 24/7 US-based support system and is backed by a three-year warranty. Overall, it is a reliable, secure, and cost-effective storage system.

Key Features

- 4 TB Total capacity with 2 Drive Bays

- Subscription-free personal cloud storage

- SSL-encrypted file transfer system

- Direct Copy function to back up your devices via USB

- 24/7 US-based support system

Specifications

- Dimension: 8.10Lx3.40Wx5.00H

- Size: 4 TB

- Unit count: 1

Pros

- Easy to set up

- No computer installation required

- Comes with all the necessary hard drives installed

- Subscription-free personal cloud storage

- Secure sharing with family and friends

- Direct Copy function to back up your devices via USB

- 24/7 US-based support system

- Three-year warranty

Cons

- No password protection on shares

- Inaccessible password-protected shares

BUFFALO LinkStation SoHo 220 is a great device for small-office and home networks. It has a vast storage capacity, and its subscription-free cloud storage, automated PC backup, and USB-direct-copy function make it a practical solution for any office or household. However, users should keep in mind some of its limitations, like the lack of password protection, quota space allocation, and the underdeveloped UI. The cost-benefit tradeoff is still positive, and with its low noise level and reliable US-based support system, this device provides excellent performance and value.

Overall Score: 7/10

MaxDigitalData 6TB 7200RPM 128MB Cache SATA 6.0Gb/s 3.5inch Internal Hard Drive is the ideal solution for NAS System (Network Attached Storage) and can be used as a desktop PC/Mac, RAID System, NAS Network Storage, CCTV DVR, Surveillance System. This high-density storage drive is designed for hyperscale applications/cloud data center solutions requiring maximum storage efficiency, and fast data access. It has a 3-years warranty from the reseller and supports a maximum cache size of 128MB. However, buyers should note that the hard drive is a bare drive only, single pack, without screws, cables, or accessories included.

Key Features

- 6TB hard disk drive

- Ideal for NAS Solutions

- Fast data access

- No Accessories included

- 3 Years Warranty

Specifications

- Dimension: 5.80Lx4.00Wx1.00H

- Size: 6TB

Pros

- Reliable for backup storage

- High capacity and cache for large data

- Great value for money

Cons

- May run hot during heavy use

- Limited compatibility with certain equipment

- Reports of hard drive failure after short-term use

Overall, the MaxDigitalData 6TB Internal Hard Drive is a decent choice for users requiring a high-capacity hard drive for data backup/storage at a great value for money. Buyers should note the bare drive-only nature, and the potential temperature issues during heavy use. Additionally, it may not work with all NAS devices, so compatibility must be checked before buying.

Overall Score: 7/10

The Western Digital 3TB My Cloud Personal Network Attached Storage provides a centralized, whole-home storage solution. It features mobile and remote web access, as well as backup and sync software for keeping content up-to-date across all your computers. The device also offers photo and video backup for smartphones and tablets, creating a common place for friends and family to share photos. It is compatible with both Windows and Mac operating systems. While some initial setup hurdles may cause frustration, the device ultimately provides an excellent network backup drive for home use.

Key Features

- Centralized, whole-home storage

- Mobile and remote web access

- Backs up PC and Mac computers

- Photo and video backup for smartphones and tablets

- Sync software to keep content up-to-date across all your computers

- Creates a common place for friends and family to share photos

Specifications

- Color: White

- Dimension: 7.60Lx8.20Wx6.30H

- Size: 3TB

- Unit count: 1

Pros

- Excellent network backup drive

- Dead quiet

- Compatible with Windows and Mac

Cons

- Initial setup can be frustrating

- Difficult to get working the way you want

The Western Digital 3TB My Cloud Personal Network Attached Storage offers an efficient, centralized storage solution with mobile and remote web access. While the initial setup may present some hurdles, it ultimately provides an excellent backup drive for home use that is quiet, compatible with Windows and Mac, and allows for easy photo and video sharing among friends and family.

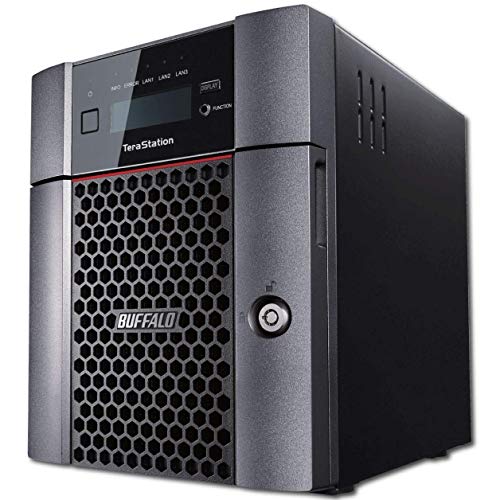

Overall Score: 9/10

The BUFFALO TeraStation 5410DN Desktop NAS is a high-quality storage solution made in Japan. It features pre-tested NAS-grade hard drives included for data protection, with 256-bit drive encryption, RAID options, a closed system, and flexible replication and backup features to keep your data safe. It is VMware Certified to expand storage capacity and extend your current servers using iSCSI and existing networking equipment, with remote management service included. The device is also cloud-integrated, syncing with Amazon S3, Dropbox, Azure and OneDrive to create a hybrid cloud for extra data security, cost savings, and flexible scalability. Additionally, the NAS transfers data 10x as fast as the 1GbE with CAT 6A or higher-rated cabling, and comes with a 3-year warranty (includes hard drive coverage) with 24/7, award-winning US-based support. It is a reliable storage device with effortless setup (RAID 5 pre-configured) and 32 TB capacity, making it perfect for movie buffs and businesses alike.

Key Features

- Made in Japan with pre-tested, NAS-grade hard drives included

- 256-bit drive encryption, RAID options, closed system

- VMware Certified with i SCSI and flexible replication and backup

- Cloud-integrated with Amazon S3, Dropbox, Azure, and One Drive

- 10x as fast data transfer speeds as 1Gb E with CAT 6A or higher-rated cabling

- Remote management service included

- 3-year warranty (includes hard drive coverage) with 24/7 US-based support

- 32 TB capacity with RAID 5 pre-configured

Specifications

- Dimension: 9.06Lx6.69Wx8.46H

- Size: 32 TB

- Unit count: 1

Pros

- Effortless setup with RAID 5 pre-configured

- Cloud integration with major providers for secure and flexible storage

- Remote management service included

- Fast data transfer speeds and 3-year warranty

- 32 TB storage with flexible RAID options

Cons

- Some users experienced issues with cloud sync and backup

- Tech support reportedly denied return for a defective item

The BUFFALO TeraStation 5410DN Desktop NAS is a reliable and efficient storage solution for both personal and business needs. It offers plenty of storage capacity with RAID options, fast data transfer speeds, cloud integration, and remote management service. Despite some reports of issues with cloud sync and backup and potential customer service problems, the device comes with a 3-year warranty and offers peace of mind with its flexible data protection features. Overall, it is a highly recommended investment for anyone seeking a secure and flexible storage solution.

Overall Score: 8/10

The TERRAMASTER F2-423 2-Bay High Performance NAS is the perfect solution for SMB High Performance Requirements. The N5095 Quad-core 2.0GHz CPU, 4GB RAM DDR4 (expandable up to 32GB) and dual 2.5-Gigabit Ethernet ports support up to 5 Gbps under Link Aggregation. This NAS is designed to support file storage servers, mail servers, web servers, FTP servers, MySQL databases, CRM systems, Node.js, and Java virtual machines, as well as a host of other commercial applications. It is also compatible with 3.5" and 2.5" SATA HDD, 2.5" SATA SSD. It supports RAID 0/1/JBOD/Single and online capacity expansion and online migration.The built-in M.2 2280 NVMe SSD slot can realize SSD cache acceleration and increase the storage efficiency of the disk array several times. Centralized Backup, Duple Backup, Snapshot, CloudSync enhance the Safety of your Data with multiple backup applications. With an aluminum-alloy shell, this small-sized compact design can be used vertically and horizontally, and with intelligent temperature control ultra-quiet fan, this NAS is good in heat dissipation and very quiet.

Key Features

- Quad-core CPU, 4GB DDR4 Memory, 2.5Gb E Port x 2

- Supports RAID 0/1/JBOD/Single

- Centralized Backup, Duple Backup, Snapshot, Cloud Sync

- 40TB Maximum Internal Raw Capacity

- Compatible with 3.5" and 2.5" SATA HDD, 2.5" SATA SSD

- Build file storage, mail servers, web servers, FTP servers, My SQL databases, CRM systems, Node.js, and Java virtual machines

Specifications

- Color: Quad-Core, 2-Bay, F2-423

- Dimension: 9.00Lx5.00Wx4.00H

- Unit Count: 1

Pros

- Expandable RAM and NVME drives

- Excellent media streaming and backup performance

- Supports large media files

- Very quiet with intelligent temperature control

- A ton of features for an Admin

Cons

- Large file transfers fail with default OS

- No instructions for setup

- Some network understanding required

The TERRAMASTER F2-423 2-Bay High Performance NAS is an excellent choice for large media files. With expandable RAM and NVME drives, backup solutions and excellent media streaming and backup performance, it’s perfect for an SMB. The default OS does have limitations, but switching to a different OS can make this NAS a solid performer and easy to use. It has many features for an Admin with tons of backup applications. Overall, with a score of 8 out of 10, it is a great buy for anyone in need of a compact, high-performance storage device.

Overall Score: 8/10

The QNAP 4 Bay DAS is an easy-to-use, pre-installed and pre-configured hard drive bundle with RAID 5 support and USB Type-C connectivity. Ideal for Windows, macOS and Linux systems, the device can be used as external storage for NAS backup and expanding the capacity of your QNAP NAS. It features four 4TB Seagate IronWolf drives with a 3-year Rescue Data Recovery Services plan, as well as USB 3.2 Gen 1 Port, lockable drive bays and hardware RAID support. The drive bays don't require screws and the doors are lockable. The QNAP 4 Bay DAS comes with a USB Type-C to Type-A connector cable, expansion slot for additional drives and dip-switches to change RAID options.

Key Features

- 4 x 4TB Seagate Iron Wolf drives pre-installed with RAID 5

- USB Type-C Direct Attached Storage for Windows, mac OS and Linux

- Supports 4 x 3.5/2.5-inch SATA 3Gb/s with lockable drive bays

- Includes a USB Type-C to Type-A connector cable

- Hardware RAID supports RAID 0, 1, 5, JBOD and individual

Specifications

- Color: Black

- Size: 4 Bay

- Unit count: 1

Pros

- Preconfigured with RAID 5

- Robust 3-year Rescue Data Recovery Services plan

- Expands QNAP NAS capacity

Cons

- Noisy fan

- Only allows 2 drives in RAID-1 at a time

- Buggy media server apps

The QNAP 4 Bay DAS is an excellent choice for those looking for an easy-to-use, pre-installed and pre-configured hard drive bundle with RAID 5 support and USB Type-C connectivity. It’s ideal for Windows, macOS and Linux systems, and can be used as external storage for NAS backup and expanding the capacity of your QNAP NAS. Although, it has some drawbacks such as limited RAID-1 options and some buggy media server apps. However, the drive bays do not require screws and the doors can be locked, making it a secure option for those who prioritize data privacy and security.

Overall Score: 7/10

The TERRAMASTER F4-210 is an entry-level 4-bay NAS optimized for home and SOHO users, running the latest TOS 4.2 operating system. It features an ARM v8 quad-core 1.4GHz CPU with 2GB RAM and fast read/write speeds of more than 114 MB/s, making it ideal for media streaming and file sharing. The F4-210 supports Emby and Plex media servers and is compatible with 3.5" and 2.5" SATA HDD, 2.5" SATA SSD. It also supports multiple applications, Docker, cloud drive sync, and remote access via mobile app. The F4-210 uses ultra-quiet heat dissipation technology, making it an excellent choice for a personal private cloud at home or office.

Key Features

- 4-bay NAS for home and SOHO users

- Quad-core 1.4GHz CPU with 2GB RAM

- Blazingly fast read/write speeds of more than 114 MB/s

- Supports Emby and Plex media servers

- Compatible with 3.5" and 2.5" SATA HDD, 2.5" SATA SSD

- Supports Docker, cloud drive sync, multiple backups

- Ultra-quiet heat dissipation technology

Specifications

- Color: 4-Bay, Quad-Core, 2GB RAM

- Dimension: 8.93Lx8.85Wx5.36H

- Unit count: 1

Pros

- Easy to set up and inexpensive

- Fast file access and media streaming

- Supports multiple applications and mobile access

- Quiet heat dissipation technology

Cons

- Limited software support for ARM units

- Lacks some advanced features advertised

- Occasional issues with setup and storage ownership

Overall, the TERRAMASTER F4-210 is a great choice for home and SOHO users looking for an affordable and fast NAS solution. While it may lack some advanced features and software support for ARM units, it offers excellent performance and easy setup, with multiple applications and mobile access. It is also quiet and energy-efficient, making it an excellent choice for those who want a personal private cloud at home or office.

Overall Score: 7/10

The MaxDigitalData 8TB Internal Hard Drive for NAS Network Storage is a high-density storage solution designed for hyperscale applications/cloud data centers solutions requiring maximum storage efficiency. With a 6Gb/s SATA interface and 256MB cache, this NAS-optimized hard drive provides ultra-high capacity 8TB for data storage. It is compatible with Desktop PC/Mac, RAID System, NAS Network Storage, CCTV DVR and Surveillance System. The drive comes with a 3-year warranty, worry-free return policy and 100% full refund. However, some users have experienced issues with the drives being faulty or loud.

Key Features

- 8TB hard disk drive designed for Hyperscale applications/cloud data centers solutions

- 6Gb/s SATA for high data integrity and fast data access

- NAS-optimized hard drive providing ultra-high capacity 8TB and cache of up to 256MB

- Compatible with Desktop PC/Mac, RAID System, NAS Network Storage, CCTV DVR and Surveillance System

Specifications

- Dimension: 5.80Lx4.00Wx1.00H

- Size: 8TB

Pros

- Ultra-high capacity 8TB

- NAS-optimized hard drive for fast data access

- 3-year warranty, worry-free return policy and 100% full refund

Cons

- Some users have experienced issues with faulty or loud drives

- One user reported the drive being labeled as 7200rpm but actually being 5400rpm

The MaxDigitalData 8TB Internal Hard Drive for NAS Network Storage is a good option for those who need a lot of storage space on a budget. While some users have reported issues with the drives being faulty or loud, the majority of users have had positive experiences with the product. It comes with a 3-year warranty and a worry-free return policy, making it a low-risk investment for those in need of an affordable storage solution.

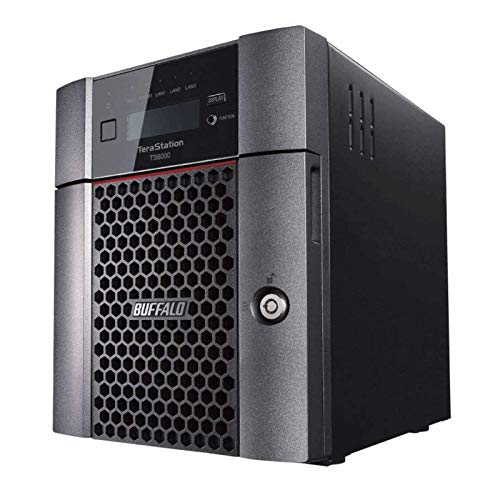

Overall Score: 8/10

The BUFFALO TeraStation 6400DN 32TB Desktop NAS comes with four NAS-grade hard drives pre-configured for RAID 5 protection and is purpose-built for data protection with its 256-bit drive encryption, a closed system, snapshots, and flexible replication and backup features. Native snapshot feature ensures data backup and protection against cyber threats such as ransomware. With 10GbE transfer speeds, you can transfer data 10 times faster than with 1GbE. The TeraStation 6400DN syncs with Dropbox, Azure, and OneDrive to create a hybrid cloud for extra data security, cost savings, and flexible scalability. The device offers a three-year warranty with 24/7, US-based support. Additionally, it is VMware certified to expand storage capacity and extend your current servers using existing networking equipment. It is also TAA compliant and qualifies for free simple logical data recovery.

Key Features

- Native snapshot for data backup and protection

- Effortless setup with pre-configured RAID 5

- 256-bit drive encryption and flexible replication

- 10Gb E for 10 times faster transfer speeds

- Cloud integration with Dropbox, Azure, and One Drive

- Three-year warranty with US-based support

- VMware certified to expand storage capacity

- TAA compliant and qualifies for free data recovery

- Remote management service saves time and resources

Specifications

- Dimension: 9.10Lx6.70Wx8.50H

- Size: 32 TB

- Unit count: 1

Pros

- Native snapshot feature for data backup

- Comes with pre-configured RAID 5

- 10Gb E for 10 times faster transfer speeds

- Cloud integration with Dropbox, Azure, and One Drive

- Three-year warranty with 24/7 US-based support

- TAA compliant and qualifies for free data recovery

Cons

- No DLNA server

- Expensive

The BUFFALO TeraStation 6400DN 32TB Desktop NAS is a reliable storage device that comes with 256-bit drive encryption, snapshots, and flexible replication and backup features to keep your data safe from cyber threats. The native snapshot feature ensures data backup and protection against ransomware. Although the device is expensive, it offers 10GbE transfer speeds and cloud integration with Dropbox, Azure, and OneDrive. Its three-year warranty with 24/7 US-based support and eligibility for free data recovery make it a sound investment. However, it does not come with a DLNA server, which could be a deal breaker for some users.

Overall Score: 7/10

The BUFFALO TeraStation WS5420DN Windows Server IoT 2019 16TB (4x4TB) Desktop NAS is a reliable storage solution with effortless setup. It features seamless integration with all Windows-friendly applications, 10GbE transfer speeds, and cloud integration with Dropbox, Azure and OneDrive. It also has virtualization capabilities, backup and disaster recovery plan, native Windows Server features, and expansive RAID options. The NAS-grade hard drives included come shipped in RAID 5 for 12 TB usable capacity, which can later change to RAID 6 for more redundancy, or RAID 0 for full 16TB capacity. With a 3-year warranty that includes hard drive coverage and award-winning US-based support, this product offers peace of mind and security.

Key Features

- Native Windows Server Io T 2019 for Storage Standard Edition

- Leverage native Windows Server features such as Shadow Copy, Azure Sync, and Active Directory

- No CALs required to save you additional integration costs

- 10Gb E transfer speeds with CAT 6A or higher rated cabling

- Sync with Dropbox, Azure and One Drive to create a hybrid cloud

- Comprehensive BDR plan with ability to back up to and from the cloud

- 16 TB capacity with NAS-grade hard drives included

- 3-year warranty with 24/7, US-based support

- Free simple logical data recovery with support when registered

Specifications

- Dimension: 9.00Lx7.00Wx9.00H

- Size: 16 TB

- Unit count: 1

Pros

- Effortless setup

- Fast transfer speeds

- Cloud integration

- Virtualization capabilities

- Expansive RAID options

- 3-year warranty with US-based support

- Free data recovery service

Cons

- Buffalo software can have issues

- Fake-failure of all drives in the array after a Windows update

- Whining fanless PSU when powered off but plugged in

- Shipped featuring Server 2016 not 2019

The BUFFALO TeraStation WS5420DN Windows Server IoT 2019 16TB (4x4TB) Desktop NAS is a high-performing storage solution with plenty of added features. The seamless integration with all Windows-friendly applications, virtualization capabilities, and cloud integration make this product an excellent choice for businesses or anyone in need of a reliable storage solution. The only downsides are the Buffalo software issues and shipped OS version. The 3-year warranty, 24/7 US-based support, and free data recovery service provide peace of mind and security. Overall, this product is definitely worth considering for its performance and bonus features.

Overall Score: 5/10

The TERRAMASTER U4-111 is an enterprise-class networked storage server designed to meet the requirements of enterprise virtualization, data-intensive applications, and service continuity. It has a powerful configuration that helps it to perform at an excellent level. With 4 X 6TB dedicated NAS hard drives in RAID 0 mode, the device’s read and write speeds can reach 650MB/s and 670MB/s, respectively. It is equipped with a built-in 10Gb Ethernet port that provides high-speed bandwidth. It is also fast, stable, and offers diversified professional applications such as file servers, mail servers, VPN servers, DHCP servers, etc. However, based on customer reviews, it has a rating of 2.6/5.

Key Features

- 1U 4 Bay Enterprise-class networked storage server

- Powerful Apollo quad-core 1.5 GHz processor

- 4GB DDR3 memory

- 10Gb Ethernet port and two 1Gb Ethernet ports

- AES NI hardware encryption

- Fast and stable with 2 network interfaces and Link Aggregation supported

- Diversified professional applications

Specifications

- Color: 4-bay U4-111

- Dimension: 27.00Lx22.00Wx7.50H

- Unit count: 1

Pros

- Highly scalable

- Enterprise version of TOS operating system

- Provides up to 10Gb of high-speed bandwidth

Cons

- Issues mounting it in a server rack

- Limited list of available apps

The TERRAMASTER U4-111 is a reasonably priced NAS that performs well in an enterprise setting. It offers a diversified professional application. It is equipped with a built-in 10Gb Ethernet port that provides high-speed bandwidth. However, some customers have reported mounting issues and limited app availability. Based on customer reviews, it has a rating of 2.6/5.

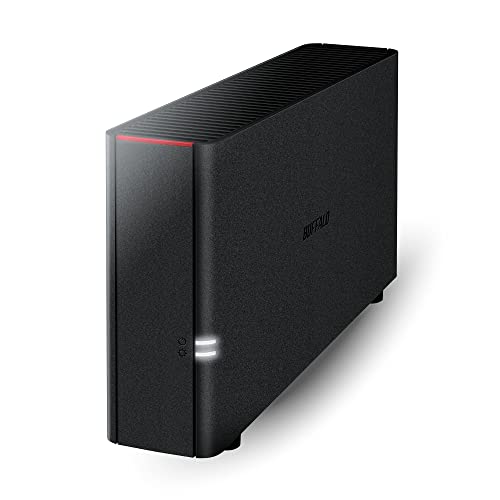

Overall Score: 7.5/10

The BUFFALO LinkStation 210 is a 4TB 1-Bay NAS Network Attached Storage device that offers hassle-free installation and serves as a home cloud or network storage solution. It comes with a hard drive included and does not require a computer for setup. With the ability to connect to your router, it provides instant shared network storage for all your devices. You can store and back up videos, music, and photos without any monthly storage charges. The NAS features a closed system for enhanced data security and supports automated backups of data on computers and mobile devices. Additionally, you can securely share files with family and friends while ensuring your data remains private. The BUFFALO LinkStation 210 is a reliable storage option with quality devices made in Japan, 24/7 US-based support, and a 2-year warranty.

Key Features

- Hassle-free installation with included hard drive

- Subscription-free personal cloud

- Purpose-built storage with data security focus

- Back up multiple computers and devices

- Securely share files with family and friends

- Organize and secure your data

- 4TB capacity

- Made in Japan

- 24/7 US-based support with 2-year warranty

Specifications

- Color: Dark gray

- Dimension: 9.45Lx3.31Wx8.67H

- Size: 4 TB

Pros

- Hassle-free installation with included hard drive

- Subscription-free personal cloud storage

- Closed system for enhanced data security

- Supports automated backups of multiple devices

- Ability to securely share files with others

- Provides an easily accessible central storage location

- Made in Japan with quality devices

- Comes with 24/7 US-based support and 2-year warranty

Cons

- Outdated software and runs constantly

- Initial setup can be confusing

- May not be as plug and play as expected

- Clunky interface and limited technical support

- Lacks data protection and error correction

- No fans, potentially leading to overheating

- Low processing power and limited RAM

The BUFFALO LinkStation 210 is a reliable and affordable NAS storage option that offers hassle-free installation, secure data storage, and easy accessibility. It provides a subscription-free personal cloud solution, allowing you to store and back up your important files without any monthly charges. With its closed system and SSL encryption, your data remains protected. The ability to back up multiple computers and securely share files adds to its convenience. However, it does have some drawbacks like outdated software, potentially noisy operation, and limited technical support. Overall, the BUFFALO LinkStation 210 is a solid choice for those seeking an entry-level network storage device.

Overall Score: 6/10

The BUFFALO TeraStation Essentials 4-Bay Rackmount NAS 16TB is a low-cost professional-grade network-attached storage device. It is designed to organize, store, share, and backup all of your important files and documents with ease. The NAS also comes with 256-bit drive encryption and features flexible replication and backup functions to keep your data safe. The device has a native 2.5GbE port for fast data transfers without requiring a cable upgrade. The hard drives come preinstalled and are configured in RAID 5, with 12 TB of usable capacity. Hybrid cloud integration is possible with sync to Amazon S3, Dropbox, Azure, and OneDrive. Additionally, the BUFFALO TeraStation Essentials 4-Bay Rackmount NAS 16TB includes a 3-year warranty with 24/7, award-winning US-based support and data recovery service. The product scores a 3.0/5 on customer rating at Amazon.

Key Features

- Low-cost professional-grade network-attached storage

- 256-bit drive encryption for data protection

- Native 2.5Gb E port for fast data transfers

- Hard drives included and RAID pre-configured

- Cloud integration with Amazon S3, Dropbox, Azure, and One Drive

- 16TB capacity with 4 pre-tested hard drives

- 3-year warranty and US-based support and data recovery

Specifications

- Size: 16 TB

- Unit count: 1

Pros

- Easy to set up and manage

- Pre-configured RAID for immediate use

- Cloud integration for extra data security

- Hard drives included in the package

- Includes a 3-year warranty with 24/7 customer support

Cons

- Issues with transfer speeds reported by some users

- Drives may not be reliable, according to some reviews

- Not an intuitive device

- Slow performance when deleting recordings

The BUFFALO TeraStation Essentials 4-Bay Rackmount NAS 16TB is an economical storage solution for businesses or individuals that need to store and back up their data. The device has a relatively simple interface that makes it easy to set up and manage, and it comes with pre-installed hard drives, so it’s ready to use straight out of the box. However, some users may encounter issues with transfer speeds, and there are reports of reliability issues with the hard drives that come with this product. Overall, the BUFFALO TeraStation Essentials 4-Bay Rackmount NAS 16TB is worth considering if you’re seeking a low-cost option for storing and protecting your files.

BUYER'S GUIDE FOR NETWORK STORAGE

Whether you are an avid gamer, a creative professional or just someone who has a lot of data to store, network storage can be a lifesaver. Network-attached storage (NAS) systems function as a central repository for all of your digital files, making them easily accessible to all devices connected to a network. NAS systems range from simple to complex and come with a variety of features. Here are some things you need to know before you buy a NAS system.

Read also: 14 Best Network Storage Device For 2024

Things to consider before buying a Network Storage

- Storage Size: Consider the amount of storage you need for all of your files. Take into account future storage needs as well.

- Number of Bays: The number of bays determines how many hard drives you can install. The more bays, the more storage you can have.

- RAID: RAID (redundant array of independent disks) allows multiple hard drives to work together and provide better performance and data protection.

- Processor and RAM: The processor and RAM are important to a NAS system's performance. For heavy usage, it's best to consider a NAS system with more processing power and RAM.

- Connectivity: The type of connectivity determines how fast and reliable your data transfer speeds will be.

- Operating System: The operating system determines the features and functionalities of a NAS system.

Types of Network Storage

- Personal Cloud Storage: Personal cloud storage is a simple NAS solution that offers remote access to files via the internet.

- Home NAS: Home NAS solutions are ideal for families that require shared storage and streaming media.

- Small Business NAS: Small business NAS solutions are ideal for file sharing, collaboration, and data backup.

- Enterprise NAS: Enterprise NAS solutions offer robust data management, faster speeds, and extensive scalability.

Features and functionalities

- Media Streaming: Media streaming is the ability to stream media files from the NAS system to a media player, TV, or mobile device.

- Backup: Backup features are critical because they allow you to automatically back up important files.

- Security: Security measures like password protection, encryption, and firewalls keep out unwanted access to your data.

- Compatibility: Compatibility with different file systems, operating systems, and software are essential in a NAS system.

- Cloud Connectivity: the ability to connect and sync between public cloud providers for better backup options.

Frequently Asked Questions about 14 Best Network Storage For 2024

A NAS system is a networked device that functions as a centralized storage solution for multiple devices. A hard drive, on the other hand, is just a single storage device that is attached to a single computer.

Yes, a NAS system can be used for gaming. It can store large games, and stream games to other devices on the network.

Yes, multiple people can access the same file at the same time on a NAS system. This makes it ideal for collaboration on shared files.

Yes, a NAS system can be accessed from outside the home network. With features like Remote Access, you can access your files while on the go.

Setting up a NAS system can be a bit technical, but most NAS systems come with user-friendly setup guides and support. With a bit of patience, anyone can set up a NAS system.

Was this page helpful?

Trust Storables.com for unbiased and honest product reviews. Our reviews are rigorously assessed by our Expert Board Contributors and adhere to strict Editorial Standards. We ensure that each review is transparent and trustworthy, helping you make informed purchasing decisions.

0 thoughts on “14 Best Network Storage For 2024”